FRICTION PLATE OF MARINE GEARBOX FRICTION PLATE

Features

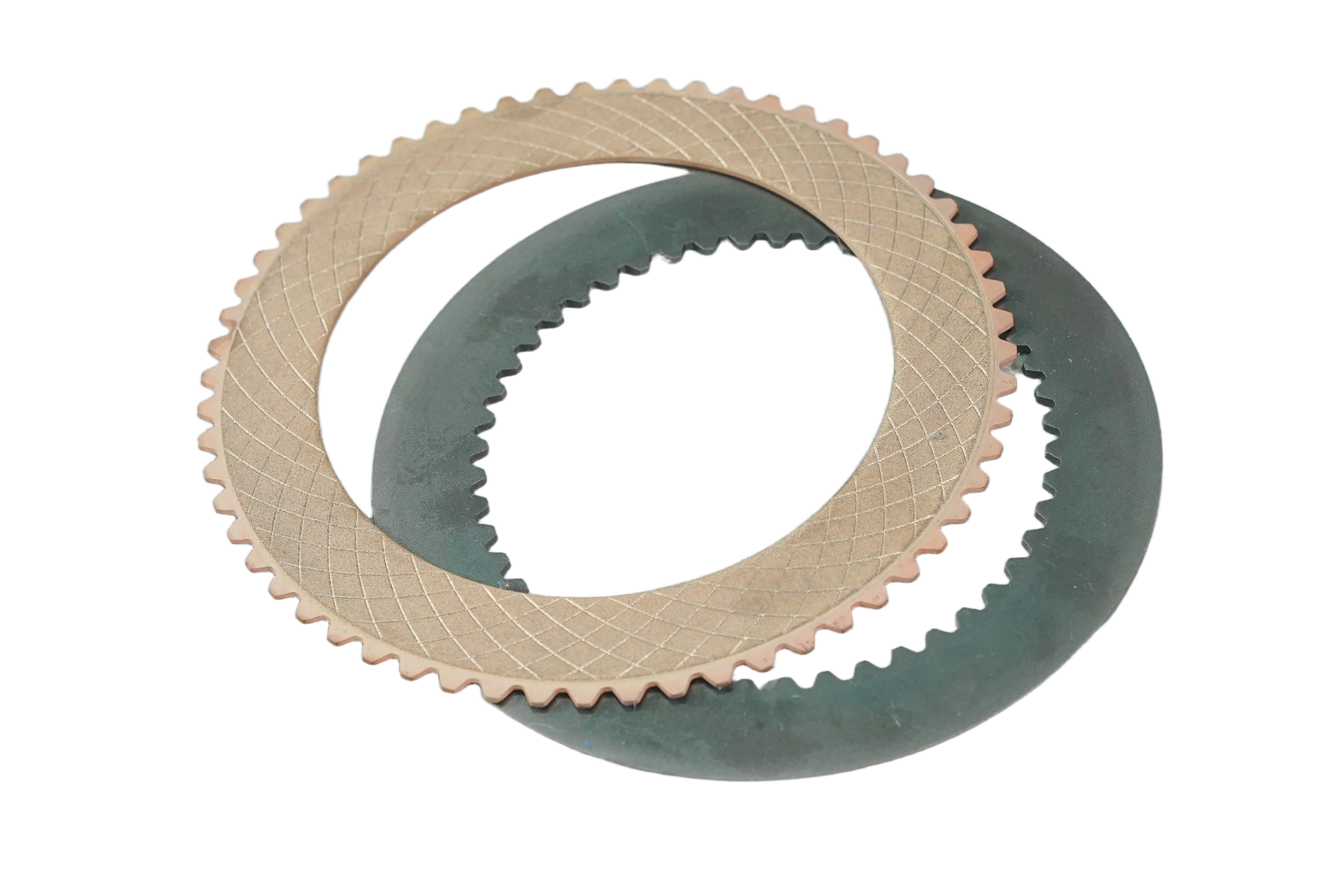

Powder Metallurgy Outer Friction Plates

Powder metallurgy friction plates are manufactured through powder pressing and sintering processes. The materials are typically copper-based powders, with additives such as graphite and molybdenum disulfide to enhance performance.

-Sintering: Heating to temperatures between 800°C and 1200°C in a protective atmosphere (such as nitrogen or hydrogen) to bond the powder particles and form a dense structure. (Miba Sintering Line)

Steel Inner Friction Plates

Steel friction plates are usually made of high-carbon steel or alloy steel, offering high strength and wear resistance.

-Quenching: Heating to a critical temperature (approximately 800°C to 900°C) followed by rapid cooling (in water or oil) to increase hardness and strength.