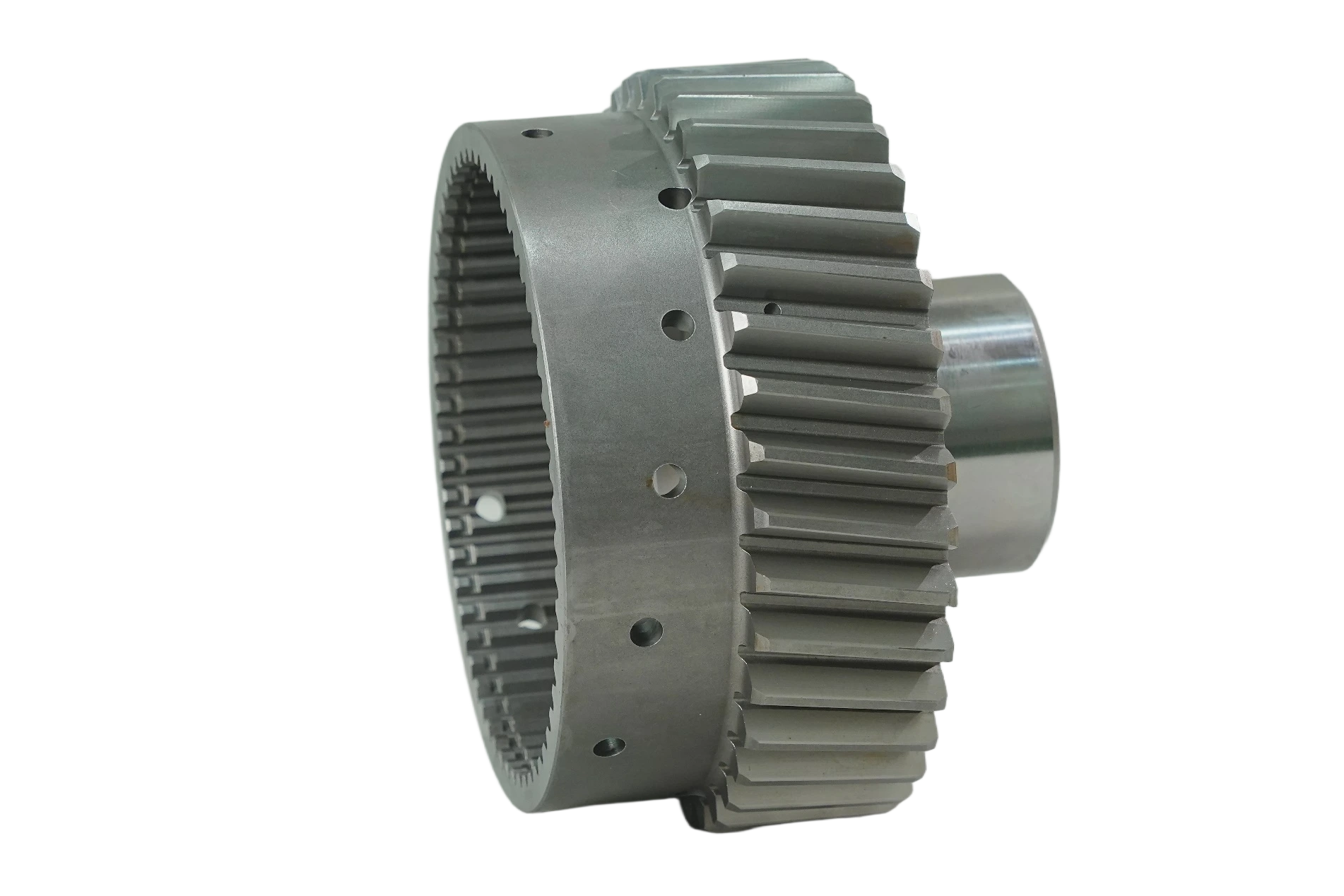

CLUTCH HOUSING OF MARINE GEARBOX CLUTCH HOUSING (Intermediate Gear)

Features

Material

The clutch housing (intermediate gear) usually made of high-strength alloy steel as follows:

-20CrMnTi : With good hardenability and toughness, suitable for bearing high loads and shocks.

-18Cr2Ni4WA: High strength and toughness, suitable for heavy duty and high-speed conditions.

Heat treatment

- Carburizing quenching: After carburizing the surface, quenching improves the surface hardness and wear resistance, while maintaining the toughness of the core. The depth of the carburizing layer is usually 0.8-1.2mm, and the surface hardness can reach HRC58-62 with core hardness HRC30-40.

-Tempering: tempering at low temperature after quenching to eliminate internal stress, improve toughness and prevent brittle fracture.

Processing

-Forging: Using precision forging to ensure material density and fiber flow, improve mechanical properties.

-Roughing: turning, milling and other preliminary forming, leaving a margin for finishing.

- Finishing: Use high-precision CNC machine tools for tooth profile machining to ensure tooth profile accuracy and surface finish.

-Gear grinding: Further improve tooth profile accuracy and surface quality through CNC grinding process to ensure smooth meshing and low noise.

Surface treatment

-Phosphating: Improve surface corrosion resistance and lubrication.