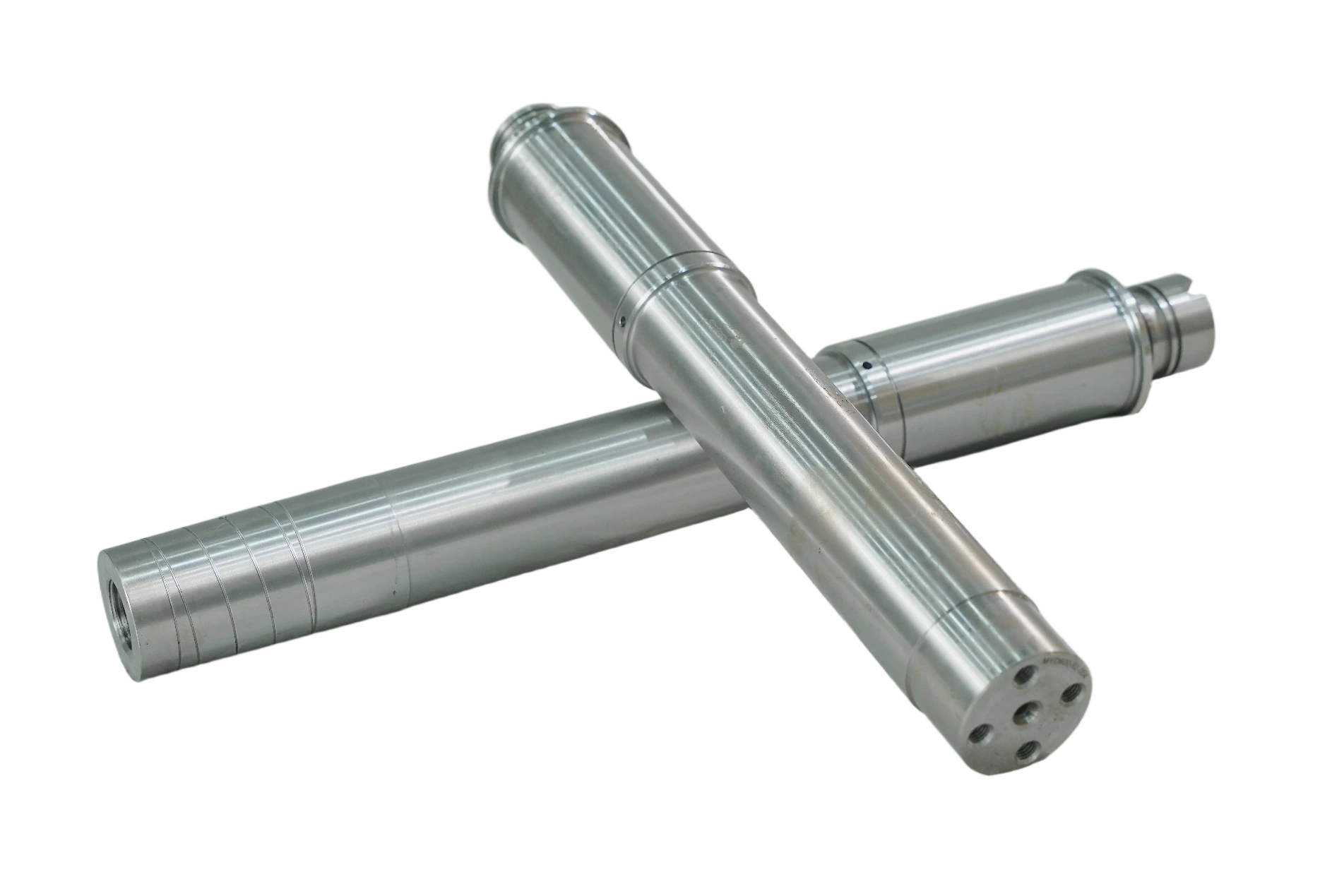

INTERMEDIATE SHAFT OF MARINE GEARBOX INTERMEDIATE SHAFT

Features

Material

The input shaft is typically made of high-strength alloy steels, such as:

- 20CrMnTi: A carburizing steel with high strength and wear resistance.

- 42CrMo: A quenched and tempered steel with excellent comprehensive mechanical properties.

- 40Cr: A quenched and tempered steel with balanced strength and toughness.

Heat treatment

- Carburizing and Quenching: Suitable for 20CrMnTi, where the surface is carburized and then quenched to achieve high surface hardness while maintaining a tough core.

- Quenching and Tempering: Suitable for 42CrMo and 40Cr, where the material is quenched and then tempered at high temperatures to achieve good overall mechanical properties.

- Surface Hardening: Achieved through induction hardening or flame hardening to improve surface hardness and wear resistance.

Processing

- Rough Machining: Forging the blank followed by rough turning, leaving machining allowances.

- Semi-Finishing: Semi-finish turning of the outer diameter and end faces to ensure dimensional and geometric tolerances.

- Heat Treatment: Carburizing and quenching or quenching and tempering, depending on the material.

- Finishing: Precision turning of the outer diameter and end faces, and grinding of critical areas to ensure dimensional accuracy and surface roughness.

- Surface Treatment: Such as chrome plating or nitriding to further improve wear resistance and corrosion resistance.

- Inspection: Including dimensional checks, hardness testing, and non-destructive testing to ensure quality compliance.