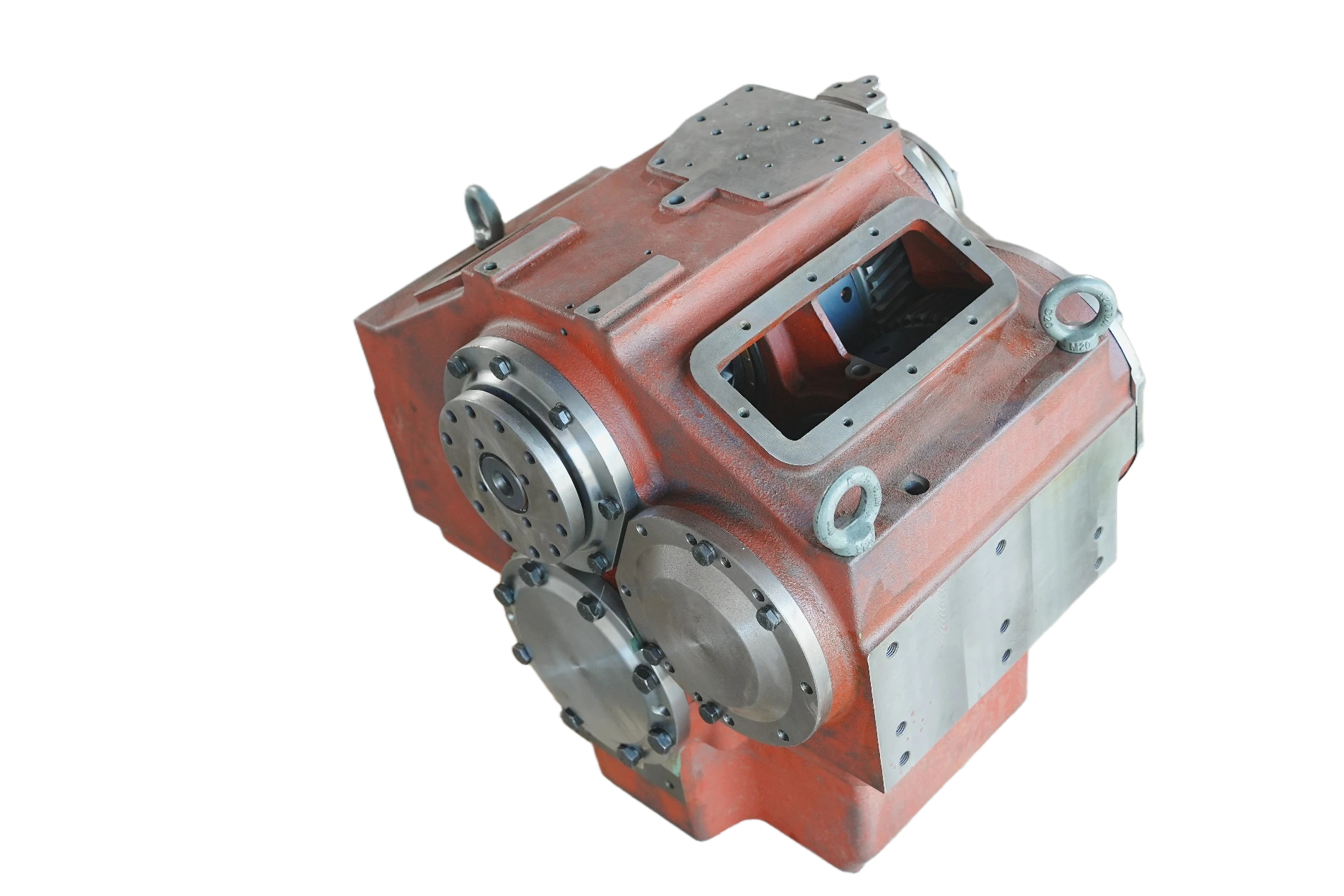

UPPER AND LOWER HOUSING OF MARINE GEARBOX UPPER AND LOWER HOUSING

Specification

| Item | Description | Parameters |

| 01 | Tooth profile accuracy | Grade 6 or higher ISO1328 or AGMA standard |

| 02 | Tooth direction accuracy | ≦0.01mm |

| 03 | Pitch accuracy | ±0.005mm |

| 04 | Surface roughness | Ra≤0.8μm |

| 05 | Module | 2-14 mm |

| 06 | Number of Teeth | as per gearbox ratio and design |

| 07 | Pressure Angle | 20° |

Features

Material

The gearbox housing for marine applications is typically made of the following materials:

- Cast Iron:

- HT250, HT300: High-strength gray cast iron, offering good casting performance, vibration damping, and wear resistance, suitable for small and medium-sized gearboxes.

- QT400-18, QT450-10: Ductile cast iron, providing higher strength and toughness, suitable for medium and large-sized gearboxes.

- Cast Steel:

-ZG230-450, ZG270-500: Cast steel material, high strength, suitable for bearing large loads and impact gearboxes.

- Aluminum Alloy:

Heat treatment

Heat treatment aims to improve the mechanical properties and durability of the housing. Common processes include:

- Annealing:

- Eliminates casting stress and improves organizational uniformity, suitable for cast iron and cast steel housings.

- Normalizing:

- Enhances the strength and hardness of cast steel housings and improves machinability.

- Aging Treatment:

- Suitable for aluminum alloy housings, eliminates internal stress, and improves dimensional stability.

- Surface Treatment:

- Shot blasting: Improves surface hardness and fatigue resistance.

- Phosphating: Enhances corrosion resistance and lubricity.

Processing

The machining processes directly affect the dimensional accuracy and assembly performance of the housing. The main steps include:

1. Casting:

- Sand casting or precision casting is used to ensure the shape and dimensions of the housing meet design requirements.

2. Rough Machining:

- Rough milling and boring of the casting blank to remove excess material and leave machining allowances.

3. Heat Treatment:

- Annealing, normalizing, or aging treatment is performed based on the material to eliminate internal stress and improve mechanical properties.

4. Semi-Finishing:

- Semi-finish machining of mounting surfaces and bearing holes to ensure dimensional and geometric tolerances.

5. Finishing:

- Precision milling and boring of critical areas (e.g., bearing holes, sealing surfaces) to ensure dimensional accuracy and surface roughness.

6. Surface Treatment:

- Shot peening, phosphating, or coating is applied to improve corrosion resistance and appearance.

7. Inspection:

FAQ