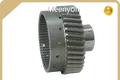

Parts: Gear Marine Transmission System Quality Assurance

Product details of the marine transmission system

Product Introduction

Meenyon can quickly develop any style marine transmission system. A team of quality people gets the product done quality every time. Meenyon is a specialty marine transmission system company who adopts high end technology.

Specification

| Item | Description | Parameters |

| 01 | Tooth profile accuracy | Grade 6 or higher ISO1328 or AGMA standard |

| 02 | Tooth direction accuracy | ≦0.01mm |

| 03 | Pitch accuracy | ±0.005mm |

| 04 | Surface roughness | Ra≤0.8μm |

| 05 | Module | 2-14 mm |

| 06 | Number of Teeth | as per gearbox ratio and design |

| 07 | Pressure Angle | 20° |

Features

Material

The DRIVEN GEAR is usually made of high-strength alloy steel as follows:

-20CrMnTi : With good hardenability and toughness, suitable for bearing high loads and shocks.

-18Cr2Ni4WA: High strength and toughness, suitable for heavy duty and high-speed conditions.

-42CrMo: High strength, good toughness and wear resistance, suitable for heavy loads and impact loads.

Heat treatment

- Carburizing quenching: After carburizing the surface, quenching improves the surface hardness and wear resistance, while maintaining the toughness of the core. The depth of the carburizing layer is usually 0.8-1.2mm, and the surface hardness can reach HRC58-62 with core hardness HRC30-40.

-Tempering: tempering at low temperature after quenching to eliminate internal stress, improve toughness and prevent brittle fracture.

-Nitriding treatment: Some gears use nitriding treatment to further improve surface hardness and wear resistance, suitable for high-speed and heavy-duty conditions.

Processing

-Forging: Using precision forging to ensure material density and fiber flow, improve mechanical properties.

-Roughing: turning, milling and other preliminary forming, leaving a margin for finishing.

- Finishing: Use high-precision CNC machine tools for tooth profile machining to ensure tooth profile accuracy and surface finish.

-Gear grinding: Further improve tooth profile accuracy and surface quality through CNC grinding process to ensure smooth meshing and low noise.

-Testing: Using coordinate measuring machine, gear testing center and other equipment to ensure that the dimensional accuracy and tooth profile error meet the requirements.

Surface treatment

-Phosphating: Improve surface corrosion resistance and lubrication.

-Plating treatment: Some gears are plated with chromium or nickel to further improve corrosion and wear resistance.

FAQ

Company Advantage

• With an excellent logistics management system, Meenyon is committed to providing efficient delivery for customers, so as to improve their satisfaction with our company.

• Set up in Meenyon becomes a leader in the industry through the development for years.

• Meenyon's Marine Gearbox,Marine Gearbox Parts,Marine Power System Solution,Marine Hydraulic Clutch gain a relatively large market share in China. They are also exported to Africa, Southeast Asia, and other countries and regions.

• Meenyon has an elite team of experienced and highly skilled professionals.

If you want to purchase our products in bulk, feel free to contact us.