| Item |

Description |

Parameters |

| 01 |

Tooth profile accuracy |

Grade 6 or higher ISO1328 or AGMA standard |

| 02 |

Tooth direction accuracy |

≦0.01mm |

| 03 |

Pitch accuracy |

±0.005mm |

| 04 |

Surface roughness |

Ra≤0.8μm |

| 05 |

Module |

2-14 mm |

| 06 |

Number of Teeth |

as per gearbox ratio and design |

| 07 |

Pressure Angle |

20° |

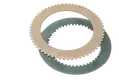

Powder Metallurgy Outer Friction Plates

Powder metallurgy friction plates are manufactured through powder pressing and sintering processes. The materials are typically copper-based powders, with additives such as graphite and molybdenum disulfide to enhance performance.

-Sintering: Heating to temperatures between 800°C and 1200°C in a protective atmosphere (such as nitrogen or hydrogen) to bond the powder particles and form a dense structure. (Miba Sintering Line)

-Heat Treatment: After sintering, quenching and tempering may be performed to improve hardness and wear resistance.

Steel Inner Friction Plates

Steel friction plates are usually made of high-carbon steel or alloy steel, offering high strength and wear resistance.

-Quenching: Heating to a critical temperature (approximately 800°C to 900°C) followed by rapid cooling (in water or oil) to increase hardness and strength.

-Tempering: After quenching, heating to a lower temperature (150°C to 600°C) to reduce brittleness and improve toughness.

Commonly used materials include high-strength alloy steels such as 20CrMnTi, 18Cr2Ni4WA and 42CrMo. These materials have high strength, good toughness and wear resistance, and are suitable to withstand high loads and impacts.

2

What are the heat treatment processes of the driving gear?

The main heat treatment processes include:

- Carburizing hardening: improve the surface hardness and wear resistance, the surface hardness can reach HRC58-62 with core hardness HRC30-40.

- Tempering: eliminate internal stress and improve toughness.

- Nitriding treatment: further improve the surface hardness and wear resistance, suitable for high-speed, heavy duty conditions.

3

What steps does the machining process of the driving gear include?

The processing technology mainly includes:

- Forging: Ensure material density and fiber flow.

- Roughing: preliminary forming, leaving a margin for finishing.

- Finishing: Using high precision CNC machine tools for tooth shape machining.

- Grinding teeth: improve tooth shape accuracy and surface quality.

- Inspection: Use coordinate measuring machine and gear inspection center to ensure accuracy.

4

What is the accuracy requirement of the driving gear?

Accuracy requirements include:

-Tooth profile accuracy: According to ISO1328 or AGMA standard, usually DIN grade 6 or higher.

-Alignment accuracy: The error is controlled within 0.01mm.

-Pitch accuracy: The error is controlled within ±0.005mm.

-Surface roughness: Ra≤0.8μm

5

What are the main dimensions of the driving gear?

The main size parameters include:

-Module: Usually 2-14mm.

-Number of Teeth: Designed according to gearbox ratio.

-Pressure Angle: Usually 20°.

-Tooth Width (Face Width): common 50-150mm.

-Outer Diameter: calculated according to the modulus and number of teeth.

Bore Diameter: Fit with shaft, usually 50-200mm.

6

What are the geometric tolerance requirements for the drive gear?

Geometric tolerances include:

-Concentricity: Control within 0.01mm.

-Parallelism: Control within 0.02mm.

-verticality: Control within 0.01mm.

7

How to check the accuracy and quality of the driving gear?

Detection methods include:

-Coordinate measurement machine: Detect geometric dimensions and form and position tolerances.

-Gear detection center: detection of tooth shape, tooth direction and tooth pitch accuracy.

-Hardness test: Test surface and core hardness.

-Surface roughness detection: Ensure that the tooth surface roughness meets the requirements.

8

What is the quality control standard for driving gear?

Quality control follows international standards (such as ISO, AGMA) or industry specifications to ensure that the dimensional accuracy, hardness, surface quality and mechanical properties of the gear meet the design requirements.

9

What are the application scenarios of Marine gearbox driving gear?

The driving gear is widely used in Marine propulsion systems, lifting equipment, construction machinery and other occasions requiring high load and high reliability.

10

How to maintain the drive gear to extend its service life?

Maintenance measures include:

-Check gear meshing and surface wear regularly.

-Keep the lubrication system working properly and use suitable lubricating oil.

-Avoid overload operation and ensure that the gear works within the rated load.

11

What is the design life of the driving gear?

The design life is usually 10-20 years, depending on working conditions, load and maintenance.

12

How to choose the right driving gear supplier?

The following factors should be considered when selecting a supplier:

-Technical competence and experience of the supplier.

- Quality control system and certification (e.g. ISO/IATF16949, ISO9001).

- After-sales service and technical support capabilities.

Company Advantages

· The wonderful color of our marine gearbox parts is big plus.

· The quality of the product is recognized by the international specification.

· The achievements all show that Meenyon's persistence and efforts on quality.

Company Features

· Since the founding, Meenyon has been involving in the design and production of marine gearbox parts. We have gained a sound reputation.

· Our company has achieved numerous honors awarded by the municipal. We are credited as the high-integrity enterprise, quality trustworthy organization, and the creditable unit keeping the promise.

· Our responsibility to the environment is clear. Throughout the entire production process, we will consume as little materials and energy as possible and increase the recyclability rate of the products.

Application of the Product

Meenyon's marine gearbox parts can be used in multiple scenes.

With Internet technology, we provide a one-stop solution for practical and effective implementation of related problems encountered in the process of purchasing products.